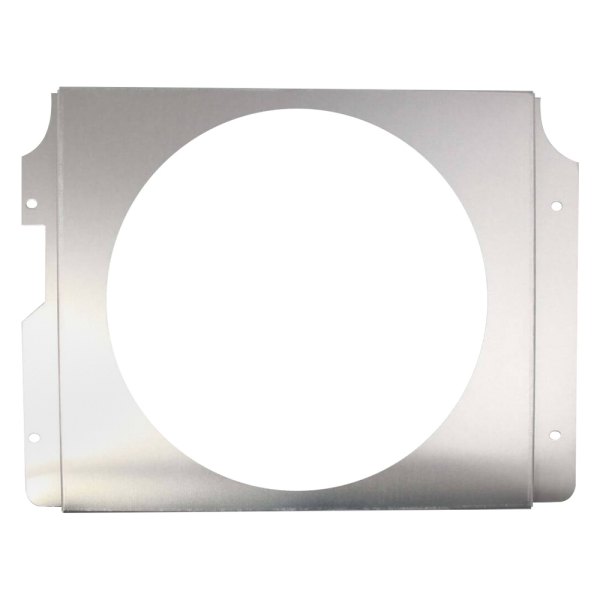

With a combination of mallets and body hammers he was able to work the aluminum to match the exact radius of the side panels. Such was the case with the homespun dolly fashioned from a section of steel pipe and some flat steel stock, which Alexander whipped up to work a 1-1/2-inch radius into the bottom of the fan shroud. Many times in order to obtain a certain look a builder must fabricate one-off tools to do the job. To work the 90-degree vertical bends into place with a graceful 1-1/2-inch radius a National finger break was used incorporating a custom roller fabricated by Alexander for the job. Using a Mittler Brothers 4-inch high-throat power drive bead roller, a step bead was completed adjacent to the lower radiator hose outlet area. Since the bottom of the fan shroud would be easily seen in the engine bay, a bit of design detail was added to infuse a bit of sex appeal to the otherwise blank area. From this pilot hole, he then measured 15-3/4 inches around with a ruler to complete the circle opening for the fan. He measured from the bottom of the top radiator tank to the water pump center pin 8-5/8 inches and marked for a pilot hole, which he drilled out with a 1/8-inch drill bit.

When locating the opening for the 15-inch flex fan, Alexander took into consideration an allowance of 3/4 inch for engine movement in keeping the gap between the fan and the shroud tight. He followed by using an MSC metal notcher to remove the bottom corner sections to allow for the upcoming bends to the sides and bottom of the shroud.

Alexander transferred all of the dimensions to a fresh sheet of aluminum using a black marker and proceeded onto the fabrication process by first trimming all excess away using a Pexto Model 152-J metal shear. For light weight and strength 0.080 6061-T6 aluminum was selected for construction of the shroud. In obtaining the radiator layback dimension details, the water pump center pin was used as an intersect point from both the bottom of the top tank and bottom tank. Alexander obtained measurements from four main points on the radiator, which included the bottom of the top tank to the bottom of the radiator core, radiator width, the water pump center pin to the radiator fins, and the layback of the radiator. Accurate measurements are crucial in keeping the overall form of the shroud nice and tight to the radiator as well as keep the unit streamlined. With the fan placement issues resolved, it was time to begin measuring for the dimensions of the fan shroud. To complete the update, he incorporated a water pump from a 250ci Chevy to the equation. To overcome this issue he installed a cast aluminum water pump riser by Zip's, which placed the water pump and mechanical fan 5 inches higher at the front of the engine. In stock form the engine's water pump is mounted far too low for the fan to be efficient.

Aluminum fan shroud how to#

With the truck being set up to run a 327ci Chevy V-8, his first order of business was to address how to effectively run a 15-inch mechanical fan.

0 kommentar(er)

0 kommentar(er)